Made from a mixture of wood flour and plant extracts, this new 3D printing ink can morph into pre-designed shapes.

Doron Kam, a Ph.D. student working on the project, and colleagues developed this technology at the Hebrew University of Jerusalem a few years ago. However, they have recently discovered that by controlling how it’s laid down, they could time how its moisture content evaporates in a way that allows it to form complex objects.

n light of all of these, it is possible to say this 3D printer ink is capable of producing wood products.

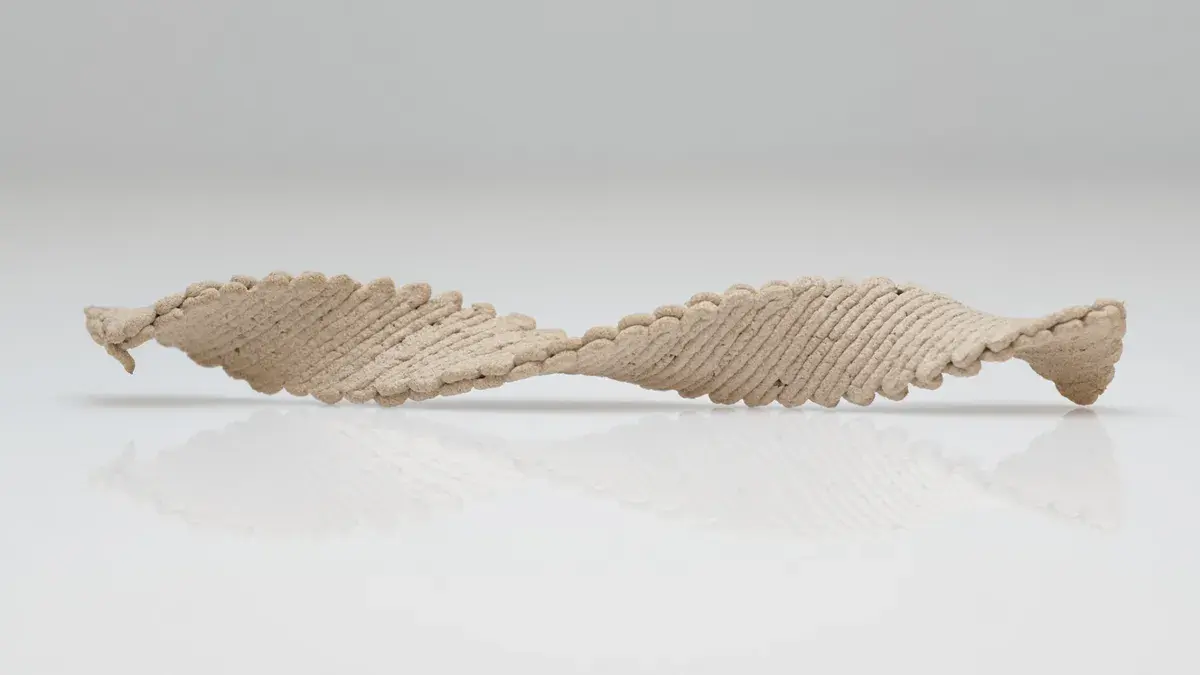

The scientists have so far used 3D printing to construct saddle, dome, and helix-shaped models out of their wood-infused ink, but with additional work, they think it might be used to make more sophisticated self-assembling products like furniture.

The technology converts organic “wood derivatives” into a paste that is then used as ink by a 3D printer. According to Doron Kam’s statement, the paste warps into the desired shape as it dries, reported in The Times of Israel.

Morphing could be challenging

Warpage may be seen as a challenge in 3D printing because of the wood’s nature, but the team is now treating it in a new way.

“Warping can be an obstacle,” explains Doron Kam, at a meeting of the American Chemical Society (ACS). “But we thought we could try to understand this phenomenon and harness it into a desirable morphing.”

It happens in two stages To create the glue, organic material is first reduced to “wood flour” and blended with two other organic materials.

The material is put into a 3D printer in the second stage, which prints a flat, 2D item. The cell structure of ordinary tree wood influences the shape the wood will distort into as it dries. With the new technique, scientists can control the cell structure and, as a result, the precise shape that the product will take when it dries and warps.